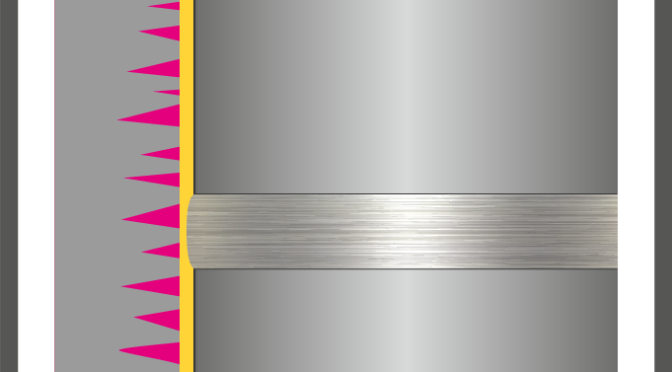

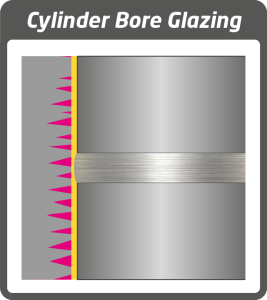

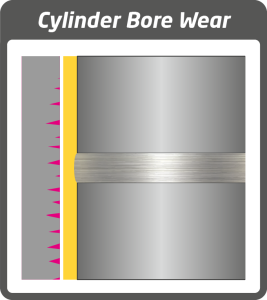

There are numerous causes of cylinder compression loss. The first is poor engine break-in. If you haven’t already done so, we recommend you read our guide on “Engine Break-in” HERE. Providing it hasn’t been left too long, and the glazing hasn’t resulted in bore polishing (bore wear), the glaze can be removed and cylinder compression restored. Left untreated, it can result in bore polishing, when the machined hone marks wear away. This can only be corrected with a re-honing of the cylinder walls.

Engine glaze is a condition where hardened oil deposits fill the asperities in the cylinder hone markings. When this occurs, engine oil has nothing to “grip” onto, so it cannot deliver the necessary lubrication and protection. It also limits the seal between the piston rings and cylinder, resulting in a loss of engine power and excess oil consumption. These hardened deposits cannot be removed with conventional engine flushes.

Another cause is poor oil quality. The oil stock can break down, burn and create a glaze. This causes combustion gases to blow by the piston rings, contaminating the oil further and thus creating a vicious cycle of oil breakdown. Neglected engines and overused engine oil can also contribute to this.

Bore glazing is particularly prevalent in engines that run idling for extended periods. This includes generators, but the issue is more commonly attributed to marine engines. Removing cylinder glazing will enable the piston rings to re-seat against the liner and ensure the lubricating oil can lubricate and protect as intended. ReleaseTech can restore such engines of any size, reducing oil consumption and excess exhaust smoke.

How to fix compression loss from suspected bore glazing?

Effective and rapid cleaning is not a simple task. It requires a much stronger and more complex product with chemistry that rapidly cleans while protecting the engine. This is not a job for a cocktail of cheap solvents. Delivering sufficient protection to the engine can be a challenge for conventional de-glazing products to the degree that cleaning performance is comprised. Many rely on the existing engine oil without adding any additional lubricity package.

Oilsyn ReleaseTech Power Flush contains unique and powerful cleaning agents within a non-interference and very lubricious and proprietary ester base, ensuring the engine is protected throughout the cleaning cycle to the degree that under professional use, the vehicle can be driven gently for a short period with ReleaseTech in the engine oil to improve cleaning performance. Cleaning power and engine protection are not compromised.

Cleaning the engine lubricating system

ReleaseTech’s powerful formula not only helps restore engine compression but will effortlessly remove deposits from within the engine and sump. Deposits are safely dispersed and held in suspension within the lubricating oil without any risk of blocking oil channels providing the oil is drained immediately after the cleaning cycle. This will improve efficiency, help extend oil life while reducing excess engine noise and clatter.

ReleaseTech Power Flush will not restore actual engine wear. Still, it remains a cost-effective way of determining if the underlying issue is engine glaze and thus provides a process of elimination before any costly strip down. If Oilsyn ReleaseTech doesn’t fix it, no other engine-flush product on the market will make a difference. Depending on the severity of wear, the engine will require an oil compression additive or, worse, a cylinder re-hone.

Customers of ReleaseTech Power Flush report improved engine performance in cases of restored engine compression but also quieter running and engine oil that stays cleaner for longer.

Oilsyn is so confident with the performance of ReleaseTech PowerFlush that it comes with a full money-back guarantee.

Please contact us should you require further information or advice.

ReleaseTech Power Flush can be purchased HERE.

categories

categories