Introduction

High-octane fuels resist engine knock, allowing higher compression ratios and improved performance. To achieve high octane, fuel blenders use anti-knock additives – compounds that boost the Research Octane Number (RON) and Motor Octane Number (MON) of gasoline. Below we examine the leading octane improvers used in racing fuels and octane boosters, detailing their chemistry, effectiveness, usage, mechanisms, and safety/regulatory aspects. A summary comparison table is provided at the end for quick reference.

Tetraethyl Lead (TEL) – Pb(C₂H₅)₄

Octane Effectiveness

TEL was the gold standard octane booster for decades. Adding mere fractions of a percent (around 0.05–0.1% by weight lead) could raise fuel octane by 5–10 RON/MON points. It enabled mid-20th-century gasolines to reach octane levels unattainable with hydrocarbons alone. TEL itself doesn’t have a “neat” RON like a normal fuel (it’s used in ppm levels), but its blending octane value is enormous.

Usage

From the 1920s to 1970s, TEL was added to virtually all automotive gasolines worldwide. It allowed inexpensive production of high-octane fuel and was critical for WWII aviation fuels and post-war high-compression engines. Today, TEL is banned in motor gasoline worldwide due to toxicity. It saw a global phase-out by the early 2000s and by 2021 was eliminated from all road fuels. The only remaining legal uses are in some aviation gas (avgas) and specialized racing fuels. For example, 100LL avgas still contains TEL (Low-Lead) to achieve MON ~100 for piston aircraft engines.

Mechanism

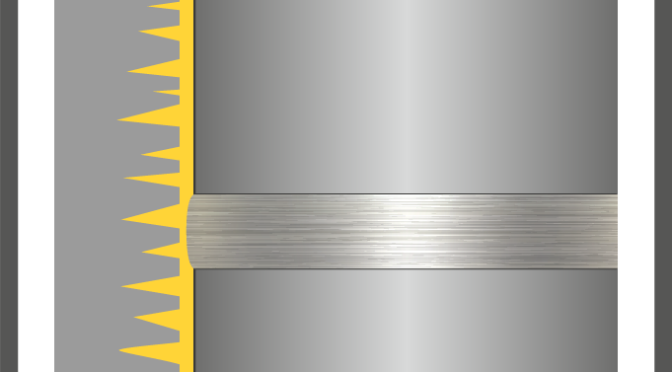

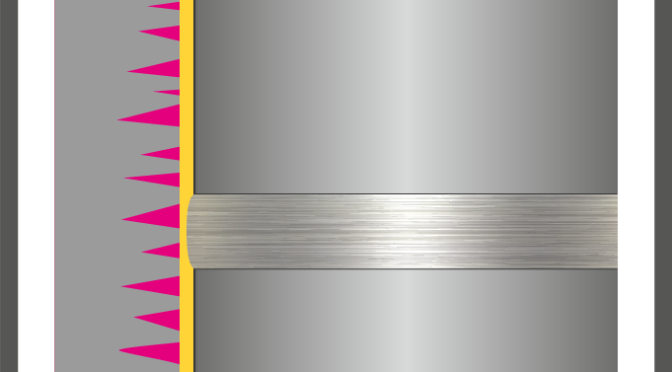

TEL’s anti-knock power comes from radical scavenging in the combustion process. In the cylinder, TEL decomposes to produce lead atoms and lead oxides that quench free radical chain reactions in the fuel’s pre-flame (the “cool flame” stage). Engine knock is driven by runaway radicals causing early detonation; lead effectively “kills” these radicals and stops knock before it starts. The ethyl groups on TEL serve only to carry lead into the fuel – the metallic lead itself is the active agent anchoring and neutralizing radicals. TEL also had a side-benefit of lubricating valve seats, reducing wear in old engines.

Environmental/Regulatory

The drawback is extreme toxicity. Lead from TEL causes neurological and developmental damage (especially in children). The combustion of TEL-laden fuel emits lead oxide particles, which led to widespread lead poisoning and environmental contamination. By the 1980s–90s, most countries enacted bans on TEL in gasoline. TEL-containing fuel (“leaded gasoline”) is now largely illegal for on-road use globally, with the UNEP declaring the official end of automotive leaded fuel in 2021. Strict regulations remain; for instance, the U.S. Clean Air Act banned TEL in cars by 1996 and only allows it in aviation or racing fuel under specific exemption. Safety: TEL is highly toxic if inhaled or ingested, and even handling the additive requires extreme caution (it’s lipid-soluble and accumulates in the body). Today, only one company produced TEL for avgas, and illegal production had been reported in the past. The cost of TEL additive is low relative to its effect, but the health and regulatory costs are prohibitive – thus its use is now confined to narrow niches where suitable unleaded alternatives are still in development (e.g. some small aircraft engines).

Methylcyclopentadienyl Manganese Tricarbonyl (MMT) – C₉H₇MnO₃

Octane Effectiveness

MMT is an organometallic octane booster that emerged as a lead replacement. It is effective in very small doses – on the order of a few hundred parts per million. For example, about 16 mL of MMT per 1000 L of gasoline (≈18 mg Mn per liter) can increase the octane rating by up to +10 RON in a low-octane base fuel. In practice, refiners might use lower doses to get a few points of octane increase. MMT’s neat RON/MON are not typically reported (it’s not used as a bulk fuel) – instead its performance is given by the boost achieved. It tends to raise RON and MON roughly in parallel (little change in sensitivity), and it can be synergistic with other additives. Studies show combining MMT with aromatic amines or oxygenates yields greater-than-additive octane boosts.

Usage

MMT saw use in unleaded gasolines starting in the 1970s as TEL was phased out. It was used in Canada for decades (introduced in 1976) and in other markets to help increase octane economically. The US EPA initially withheld approval over health concerns, but a court ruling in 1995 forced the EPA to allow MMT in unleaded fuel. For a time in the late 1990s, MMT appeared in some US gasolines, but it never saw universal use. Many oil companies voluntarily avoided MMT due to potential engine and emissions impacts. MMT was also used in countries like Australia, Russia, and parts of Asia/Africa in the 2000s. However, by the 2010s, its use declined significantly: the Worldwide Fuel Charter (a global automaker guide) recommended against MMT, and jurisdictions like Europe, Japan, etc., forbid or severely limit it. As of the 2020s, MMT is banned or capped in the EU and many other regions, and in the US, it is not used in mainstream pump gasoline (even though it is legally permitted up to 8.3 mg Mn/L). It still finds use in some off-road fuels, racing gasoline, or octane booster additives sold to consumers. For instance, certain aftermarket “octane booster” products contain MMT (noted by an orange-colored tint and manganese content on the label).

Mechanism

Like TEL, MMT functions via combustion chemistry modification. When MMT burns, it forms microscopic manganese oxide particles. These Mn oxides perform a similar role as lead oxide – they scavenge free radicals in the fuel-air mixture, thereby raising the knock threshold. The manganese acts as a combustion inhibitor that slows the explosive pre-ignition reactions. The result is a smoother, controlled burn and higher octane. MMT was found to reduce engine knock without significantly altering bulk flame speed, indicating it targets the auto-ignition chemistry in the end-gas. MMT’s anti-knock mechanism is less thoroughly documented in open literature than TEL’s, but it’s understood to be a “lead-like” action of metal particles quenching hot radicals. One difference: the solid manganese oxide formed does not vaporize like lead halides, so it tends to stay in the engine/exhaust.

Environmental/Regulatory

MMT’s controversy stems from its health and engine impact. MMT is a neurotoxin – manganese is an essential element in small doses, but chronic inhalation of manganese particles can cause a Parkinson-like neurological disorder. Regulators feared that widespread MMT use would elevate Mn emissions. Studies in Canada and elsewhere showed mixed results: manganese levels in air did rise in some urban areas using MMT, but often remained within regulatory limits. Nonetheless, uncertainty about long-term exposure risks led many countries to adopt a precautionary ban.

Engine and emissions issues: MMT combustion products (Mn₃O₄, etc.) can deposit in engines and catalytic converters. Drivers and mechanics observed orange-brown deposits on spark plugs, oxygen sensors, and catalysts when using MMT-treated fuel, potentially causing misfires or catalyst plugging. Automakers complained MMT could impair onboard diagnostic sensors and increase tailpipe hydrocarbons. MMT’s manufacturer claims that it does not harm catalyst performance at recommended low concentrations, and some studies showed no significant difference in emissions. Even so, the trend is toward the elimination of MMT in commercial fuels. Many fuel standards (e.g. Euro V/VI) set manganese at 0 mg/L. In the US, MMT is technically allowed but subject to a health effects testing provision; it’s essentially absent from branded gasoline. In China, it was banned in 2013; Russia banned it in Euro-5 gasoline as of 2016.

MMT is still produced (often under the trade name HiTEC® 3000) and is used in certain markets or racing fuels. It is relatively low-cost – a big appeal to refiners since a few ppm can replace a larger volume of expensive high-octane blend stock. But given regulatory and liability issues, most refiners have moved to other octane boosters.

Ferrocene – Fe(C₅H₅)₂

Octane Effectiveness

Ferrocene (an iron organometallic) is another metal-based antiknock agent. It is quite effective per dosage, though not as potent as TEL or MMT. Typical ferrocene additive concentrations are in the tens of ppm of iron. On the order of 170 grams per 1000 kg of fuel (≈30–40 mg Fe per liter) yields about a 4–5 point increase in octane number. In other terms, ~0.017% ferrocene by mass can raise RON from, say, 88 to 92. It boosts MON as well. Ferrocene’s neat RON isn’t usually given (it’s a solid at room temp and used dissolved in a carrier), but it behaves as a high-octane component. It’s considered the cheapest way to improve octane on a cost-per-point basis in some refinery studies.

Usage

Ferrocene saw interest as a leaded-fuel replacement in the 1990s, particularly to allow classic cars to run on unleaded fuel. It’s commercially available in aftermarket gasoline additives (often marketed as octane boosters or “lead substitutes” for vintage engines). Fuel-grade ferrocene is typically a soluble solution added at the refinery or by the end-user. Some small-market gasoline blenders in regions without strict standards have used ferrocene to cheaply elevate octane. However, major fuel suppliers in developed countries generally do not use ferrocene in pump gasoline (it’s not registered for use by many regulators). In motorsports, ferrocene has seen use in certain racing gasoline formulations and in drag racing fuels (especially where leaded fuel is disallowed but high octane is needed). It’s also used in other industries – e.g., as a combustion catalyst in diesel/jet fuels to reduce smoke.

Mechanism

Ferrocene’s anti-knock function is analogous to other heavy metal additives: it decomposes during combustion to form iron oxides. These iron particles act as radical scavengers, interrupting the chain reactions that lead to knock. Essentially, ferrocene delays the auto-ignition of the fuel-air mixture by quenching free radicals (thus raising the fuel’s effective octane). Additionally, ferrocene deposits a thin layer of iron oxide on metal surfaces. In older engines, this provided some valve seat protection (similar to how lead deposits prevented valve recession). Unlike TEL, ferrocene does not require halogen “scavengers” – the iron oxides formed are solid particulates that mostly exit with exhaust or remain as a fine powdery deposit.

Environmental/Regulatory

Ferrocene is considered far less toxic than organolead or MMT. However, the iron oxide particles from combustion can still pose issues: they can foul spark plugs (leaving a reddish-brown residue), contaminate lubrication oil, and coat exhaust system components. High dosing of ferrocene leads to plug whiskering and deposits. Many jurisdictions implicitly ban ferrocene by prohibiting any metal in unleaded fuel. For example, the European fuel specification (EN 228) limits iron content to very low levels, effectively zero for intentional addition, and Euro V standards prohibit ferrocene use. In the US, ferrocene is not an EPA-registered fuel additive for on-road use. Countries without modern emissions standards have fewer restrictions, so ferrocene is still “actively used” in some places with no Euro 4/5 rules. It’s popular in parts of the Middle East and Africa as an octane improver for substandard fuel.

Engine warranty: Car manufacturers generally warn against ferrocene additives because of deposit concerns. Cost/availability: Ferrocene is relatively cheap and easy to manufacture. Because only small quantities are needed, it’s an economical option for fuel blenders if legally allowed. On the retail side, ferrocene-containing boosters are sold under various brand names. Given its limitations, ferrocene is best suited for controlled use (e.g., one bottle to treat a tank in a classic car occasionally, or carefully metered doses in racing fuel) rather than continuous use in modern cars.

Ethanol – C₂H₅OH (and other Alcohols)

Octane Effectiveness

Ethanol is a high-octane oxygenate widely used in gasoline. Pure ethanol has a RON of about 108–109 and MON ~89–90. This large RON and decent MON mean ethanol has an octane index higher than typical gasoline components. When blended, ethanol’s blending octane number can exceed its neat octane due to nonlinear effects (especially in low-octane fuel). For instance, adding 10% ethanol (E10) to base gasoline often raises the RON by ~2 to 3 points and MON by ~1 to 2 points. Higher blends yield larger boosts: going from E10 to E20 can add ~4–7 RON points in total. E85 can be around 100–105 (R+M)/2, roughly 108+ RON. Methanol (CH₃OH), another alcohol used in racing, has similar high octane (RON ~109, MON ~88).

Usage

Ethanol is one of the most common octane enhancers today. In contrast to other additives that are used in ppm levels, ethanol is blended in significant volume (several vol%). In many countries, E10 (10% ethanol) gasoline is standard pump fuel. The ethanol boosts octane and also serves as a renewable fuel component. The U.S., Europe, Brazil, China, and others all use ethanol-blended gasoline. In the US, virtually all “regular” gasoline contains ~10% ethanol, contributing about 3 octane numbers (allowing base gasoline of ~84 AKI to be sold as 87 AKI). Some premium fuels also contain ethanol (e.g., “95 E10” in EU or certain 100 RON fuels with 5–10% ethanol). Higher ethanol blends like E15 (15%) are approved for many modern cars in the US. E85 (85% ethanol) is used in flex-fuel vehicles and has very high octane. In racing, ethanol or methanol fuels are popular for high knock resistance and cooling effect.

Mechanism

Ethanol improves octane primarily through its inherent combustion characteristics and charge cooling:

- High heat of vaporization lowers intake charge temperature.

- The oxygen bound in ethanol leads to a leaner mixture in the cylinder, delaying auto-ignition.

- Blending synergy can increase the octane more than predicted by linear mixing rules.

Environmental/Regulatory

Ethanol is seen as a cleaner additive – it reduces tailpipe CO and particulate emissions by oxygenating the fuel, and it’s biodegradable. It also comes from renewable sources (corn, sugarcane, cellulosic biomass), so it can lower net CO₂ emissions. Governments actively promote ethanol through mandates or incentives. There is no ban on ethanol; rather, there are minimum blending requirements in many regions. Downsides include a higher Reid vapor pressure (which can increase evaporative emissions), potential aldehyde emissions, and corrosion issues with older materials. Overall, ethanol is considered an environmentally beneficial octane booster, and virtually all modern gasoline cars are designed to run on at least E10. Ethanol is produced on a large scale; it typically has lower energy density, so fuel economy is slightly reduced.

MTBE (Methyl tert-Butyl Ether) – C₅H₁₂O

Octane Effectiveness

MTBE is a fuel ether that was widely used to boost octane. It has a high intrinsic octane: roughly RON 117–118 and MON ~101. In gasoline blends, MTBE gave strong octane improvement – adding 10% MTBE could increase RON by on the order of 5 points. Because MTBE raises both RON and MON, it was effective in enhancing the anti-knock index.

Usage

MTBE became the preeminent octane booster of the 1980s–90s after lead was removed. Refiners blended MTBE at ~5–15% in reformulated gasoline in the US and parts of Europe. It was also used to meet oxygenate requirements in some areas. By the early 2000s, MTBE use in the US declined sharply after widespread groundwater contamination was discovered. Many states banned or restricted MTBE, and refiners switched to ethanol. In Europe, MTBE is not entirely banned but is often replaced by ETBE (ethyl tert-butyl ether). Asia and the Middle East continue to produce and use MTBE.

Mechanism

MTBE improves octane by being a stable, high-octane component that dilutes more knock-prone hydrocarbons. Its oxygen content also helps with more complete combustion.

Environmental/Regulatory

MTBE is water-soluble and persistently contaminates groundwater if leaked. Even low levels can impart a strong taste/odor to water. While not definitively classified as a human carcinogen in all jurisdictions, health concerns and community backlash over water contamination drove its phase-out in many regions. Where ethanol logistics are less developed, MTBE may still be used, but storage systems must be carefully managed.

Aromatic Hydrocarbons: Toluene (C₇H₈) and Xylene (C₈H₁₀)

Octane Effectiveness

Aromatics such as toluene and xylenes are naturally high-octane components of gasoline. Toluene has a RON of around 120 and a MON near 109, while xylene is similar. Adding aromatic content to fuel raises its octane. In racing fuels, large percentages of toluene (sometimes exceeding 50%) have been used to attain very high octane numbers.

Usage

Commercial gasoline often contains 20–30% aromatics (including toluene, xylenes) from catalytic reforming. They are also used as direct octane boosters in some blends or aftermarket solutions. Toluene is a popular DIY octane booster, as it’s readily available in paint solvents. However, high aromatic content is regulated in many regions due to emissions concerns.

Mechanism

Aromatic rings are stable and resist auto-ignition due to their structure. They slow the formation of knock-driving radical chains.

Environmental/Regulatory

Although less carcinogenic than benzene, toluene and xylene can increase smog, particulate emissions, and NOx due to higher flame temperatures. Many fuel regulations now cap total aromatics (e.g., to 25–35%) to limit pollution. Overuse of aromatics can also cause deposit formation and material compatibility issues if extremely high in the fuel.

N-Methylaniline (Mono-Methyl Aniline, MMA) – C₆H₅NHCH₃

Octane Effectiveness

N-Methylaniline is an aromatic amine with exceptional octane-boosting power. Even low concentrations (1–2%) in gasoline can yield large octane gains. It can be synergistic with metal or oxygenate additives, further elevating the octane rating.

Usage

Historically, aniline derivatives were among the earliest anti-knock agents studied (even predating TEL). However, they were overshadowed by TEL. N-Methylaniline has been used in some countries as a cheap, unregulated booster. It appears in certain aftermarket octane boosters marketed as “racing” or “off-road use only.” Major fuel suppliers generally do not use NMA because it is banned or heavily restricted.

Mechanism

Aromatic amines feature high inherent knock resistance and may also act as radical scavengers, stabilizing reactive intermediates that drive knock. They can help drastically raise both RON and MON.

Environmental/Regulatory

N-Methylaniline is toxic and can promote gum, varnish, and soot formation at higher doses. Many jurisdictions effectively ban aniline-based additives by limiting nitrogen content in fuel. Overuse can also increase NOx and other harmful emissions. Consequently, it remains largely absent from official fuel specs but may be used illicitly or in some racing contexts.

2,2,3-Trimethylbutane (Triptane) – C₇H₁₆

Octane Effectiveness

Triptane is a highly branched paraffin with a RON of around 112–113 and MON ~101. Small amounts can significantly boost the octane of lower-quality gasoline beyond linear predictions. This non-linear blending advantage led to it being called a “super fuel” component.

Usage

During WWII, triptane was manufactured in limited quantities for aviation gasoline experiments. While beneficial for octane, it was difficult and expensive to produce at scale. It remains a research focus; modern methods are exploring bio-derived triptane as a potential drop-in high-octane blendstock.

Mechanism

Its structural branching resists auto-ignition, and in blends, it can suppress knock-prone reactions of other components. Unlike metal or amine additives, it simply contributes its own high knock resistance.

Environmental/Regulatory

No unique toxicity concerns. it’s just another hydrocarbon. Cost and production limits have historically prevented large-scale adoption. If production becomes economical, it could serve as a valuable high-octane blend stock without heavy metals or toxic side effects.

Comparison Table

| Compound (Formula) | Octane Boost & Mechanism | Usage & Status |

|---|---|---|

| Tetraethyl Lead (TEL) Pb(C₂H₅)₄ | +5–10 RON/MON boost with ~0.1% addition. Lead oxide scavenges radicals, quenching pre-ignition chain reactions. | Historic leaded gasoline additive; banned globally for road fuel due to extreme toxicity. Still used in 100LL avgas and some racing fuels. |

| MMT (Methylcyclopentadienyl Mn tricarbonyl) C₉H₇MnO₃ | Up to +10 octane numbers at ppm levels. Manganese oxides formed on combustion quench free radicals (TEL-like). | Used as lead substitute in some unleaded gasolines. Restricted or banned in many regions due to neurotoxicity and catalyst deposits. |

| Ferrocene Fe(C₅H₅)₂ | ~+4–5 RON boost at ~30 mg/L Fe. Iron oxides inhibit knock. | Aftermarket additive for older and modern engines; susceptible to deposit issues if overdosed. Also appears in some racing blends. |

| Ethanol (EtOH) C₂H₅OH | Neat RON ~109, MON ~90. High latent heat (charge cooling) and oxygen content reduce knock. | Widely used as E10-E85 in commercial and racing fuels. Renewable, mandated in many regions, lowers net emissions. |

| MTBE (Methyl tert-Butyl Ether) C₅H₁₂O | RON ~118, MON ~101. Stable, oxygenated component dilutes low-octane hydrocarbons. | Once the main oxygenate for reformulated gas; banned or restricted in some areas due to groundwater contamination. Still used in parts of Asia/Middle East. |

| Toluene/Xylenes (Aromatics) C₇H₈, C₈H₁₀ | RON ~115–120. Aromatic rings resist auto-ignition, raising RON/MON. | Common in refinery blends, regulated for emissions. Popular as a DIY or racing octane booster. Toluene is now restricted in the EU due to toxicity. |

| N-Methylaniline (Aromatic Amine) C₆H₅NHCH₃ | Extremely high blending octane (can synergize with metals/oxygenates). | Largely banned in modern fuel specs due to toxicity, deposits, and NOx concerns. Some niche/racing use. |

| 2,2,3-Trimethylbutane (Triptane) C₇H₁₆ | RON ~112, MON ~101. Highly branched structure yields strong non-linear blending benefits. | Historical interest for aviation. Not widespread commercially due to production cost. Potential future biofuel. |

categories

categories